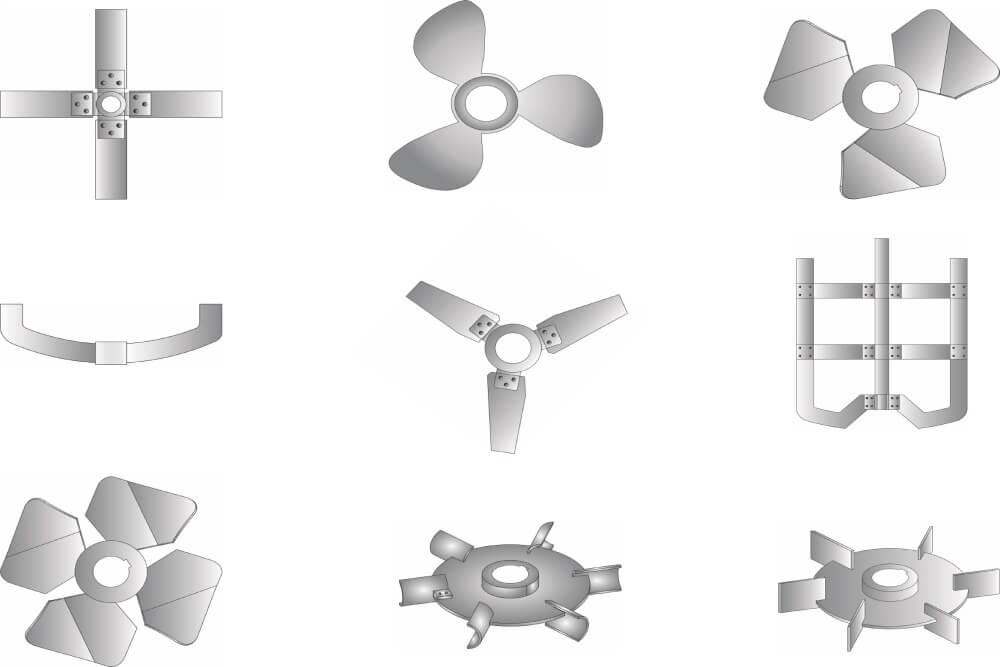

Impellers

Precision-Engineered Mixing Components

Fluid Mixing Technologies proudly presents a range of precision-engineered Impellers, crucial for achieving efficient mixing across various industrial applications. These impellers are designed to optimize fluid movement and ensure superior mixing performance.

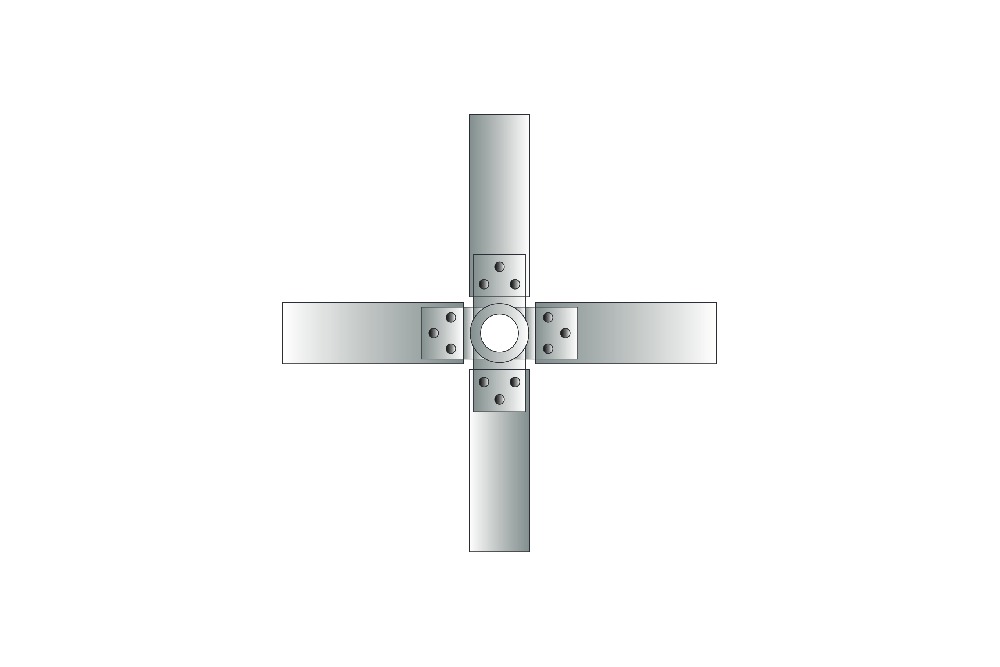

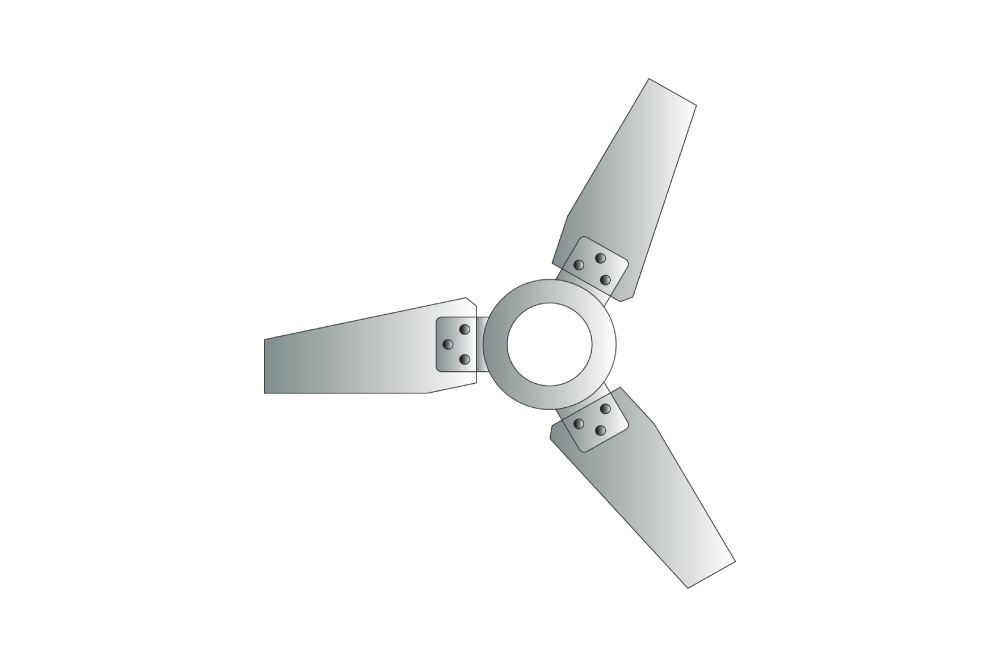

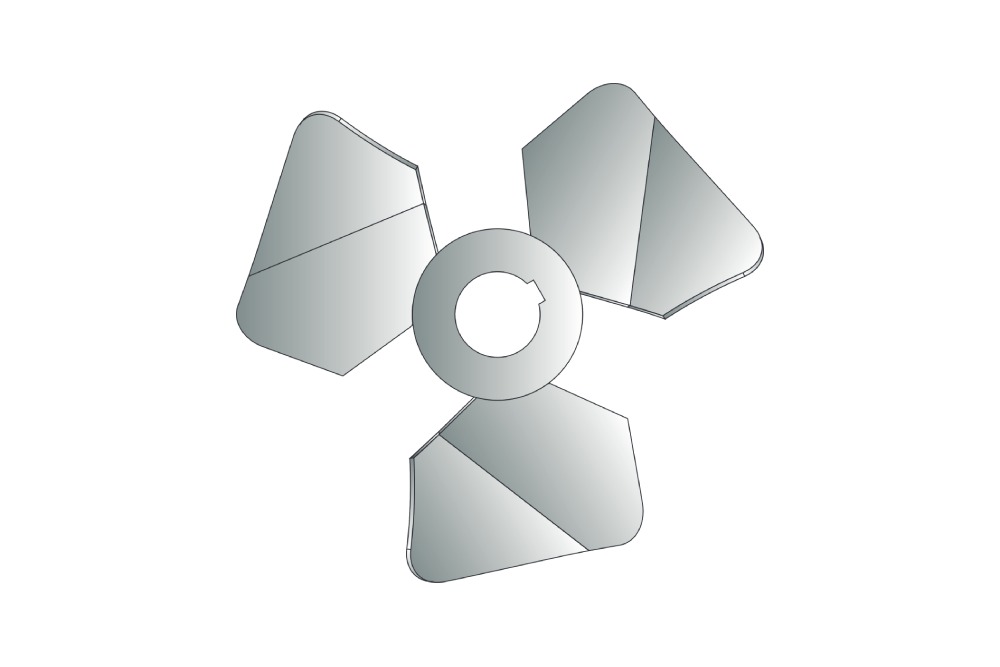

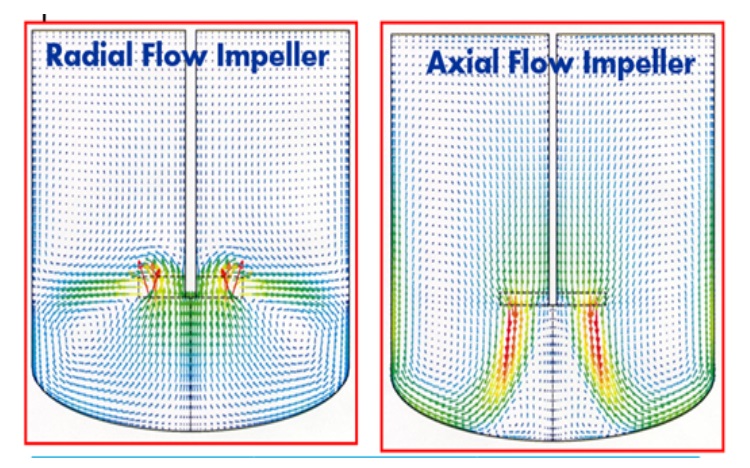

Axial Flow Impellers:

AF1: Pitch Blade Turbine (PBT): Ideal for blending, solid suspension, and heat transfer.

AF2/AF3: Hydrofoil: A high efficiency hydrofoil, designed for efficient fluid mixing with huge power savings

AF4: Wide Blade Hydrofoil: Efficiently handles high-viscosity materials like polymers and adhesives, Excellent for handling up to 150,000 cP viscous fluids.

AF-5: Gas-Liquid Impeller: Specifically designed for gas-liquid mixing applications.

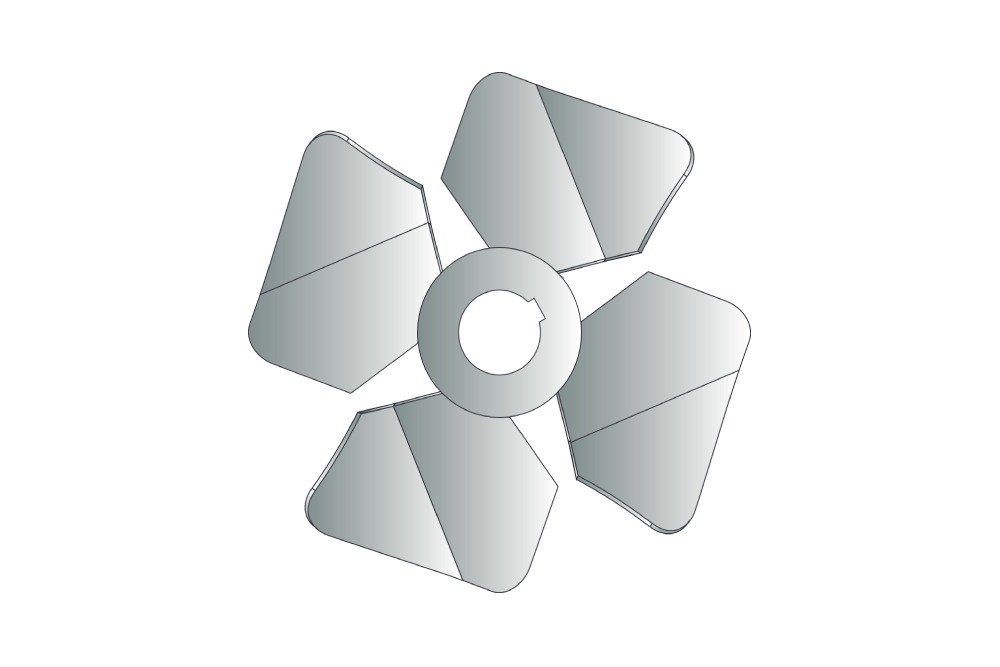

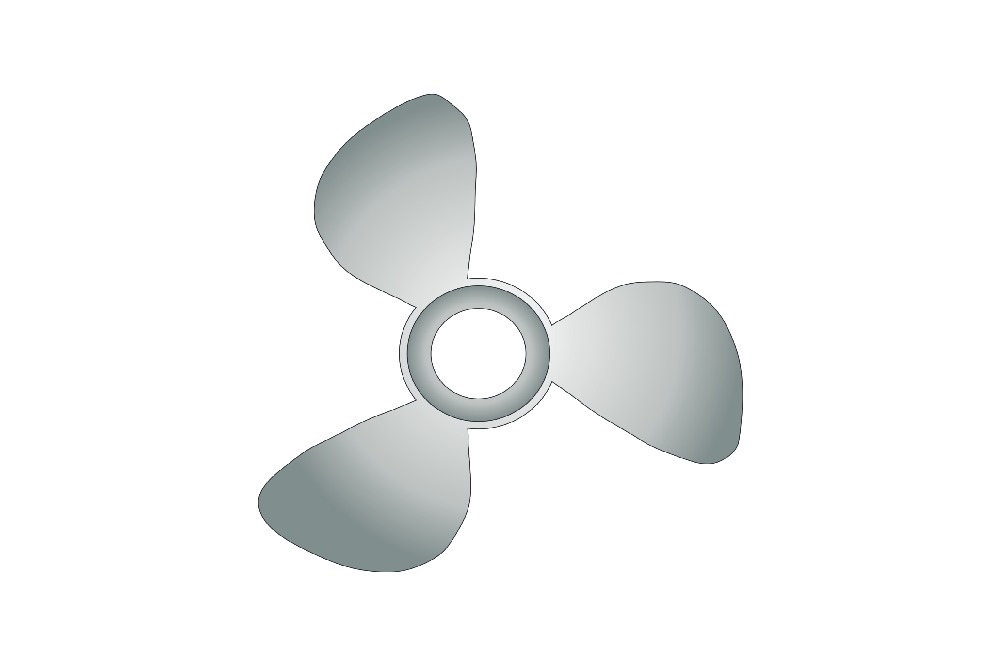

AF-6: Marine Propeller: High-shear capabilities suitable for intense mixing applications.

Radial Flow Impellers:

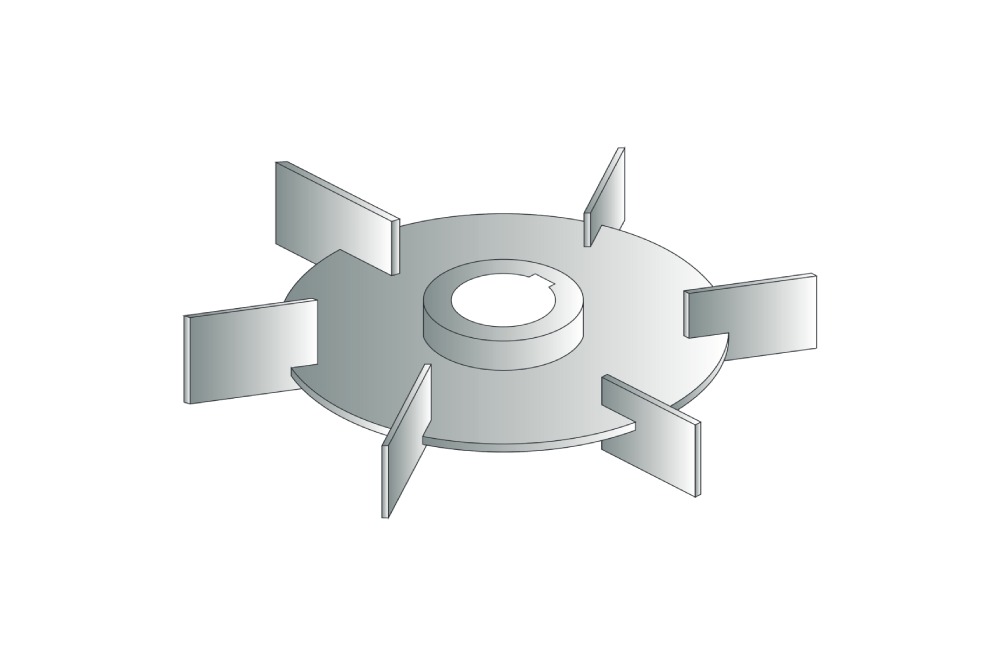

RF1: Rushton/Flat Blade Turbine (FBT): Primarily known for gas-liquid mixing applications.

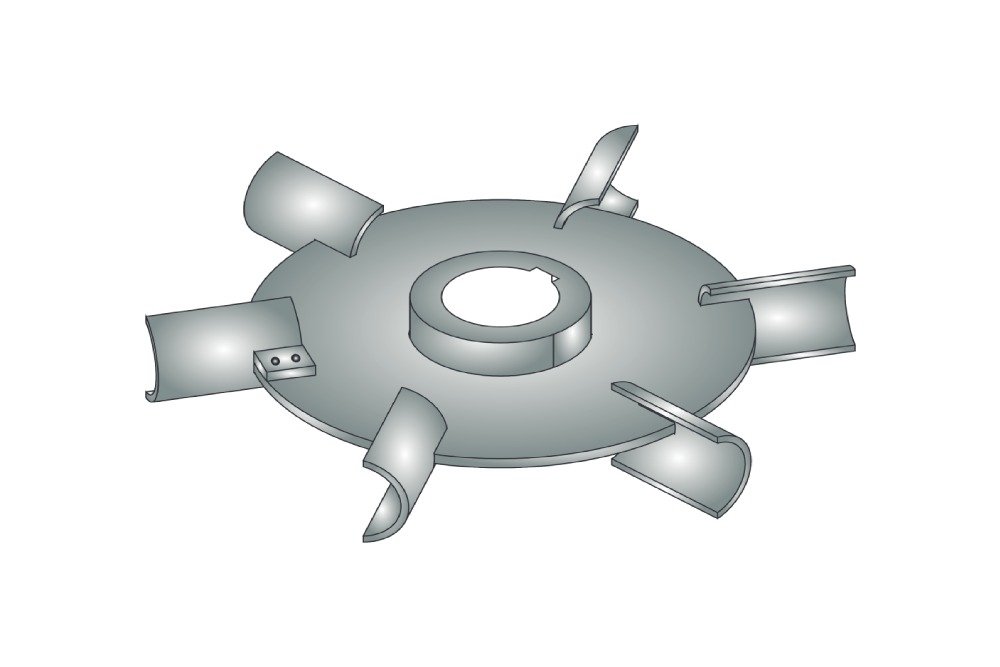

RF2: Smiths/Curved Blade Turbine (CBT): Ensures effective gas dispersion and mass transfer.

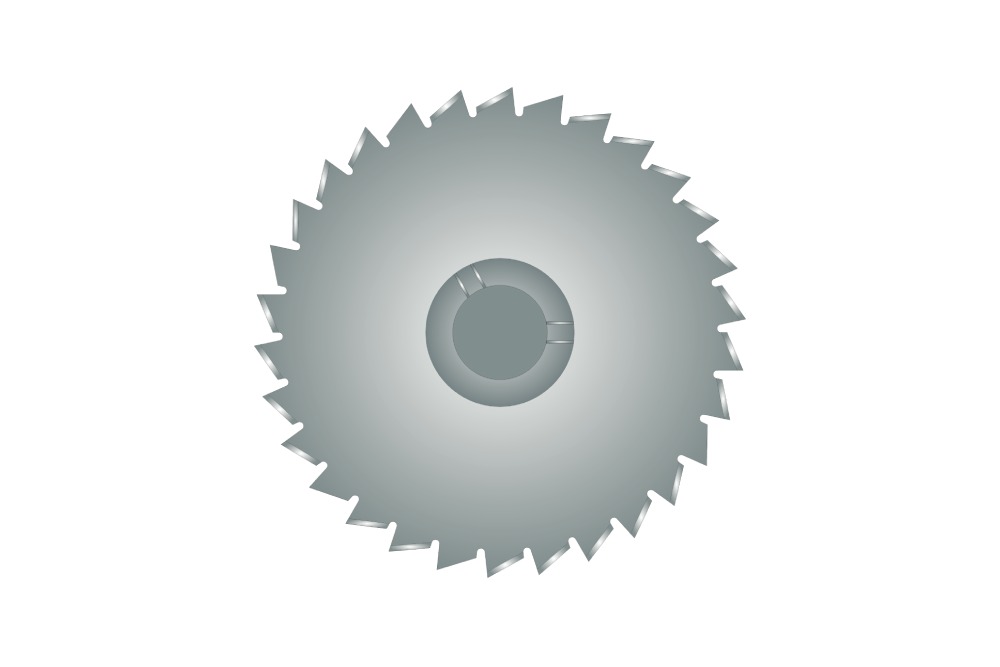

Cowls Disk/Saw Tooth: Specialized for high-shear mixing applications.

Features

Varied Impeller Types

Covering different mixing requirements and viscosities.

High-Efficiency Design

Optimized for specific applications and mixing scenarios.

Diverse Materials

Available in Austenitic, Duplex, Alloy steel, and other specialized coatings.

Viscosity Range Adaptability

Catering to fluids from low to extremely high viscosity.

Benefits

- Versatile Functionality: Suited for a wide array of industrial mixing requirements.

- Precision Engineering: Ensures efficient fluid movement and optimal mixing performance.

- Viscosity Compatibility: Handles a broad range of fluid viscosities with ease.

- Enhanced Mixing Capabilities: Facilitates superior gas-liquid interaction and mass transfer.

Fluid Mixing Technologies’ Impellers are essential components, offering precision and versatility in achieving efficient and effective mixing across diverse industrial applications.